Sustain manufacturing system performance with data-driven decisions.

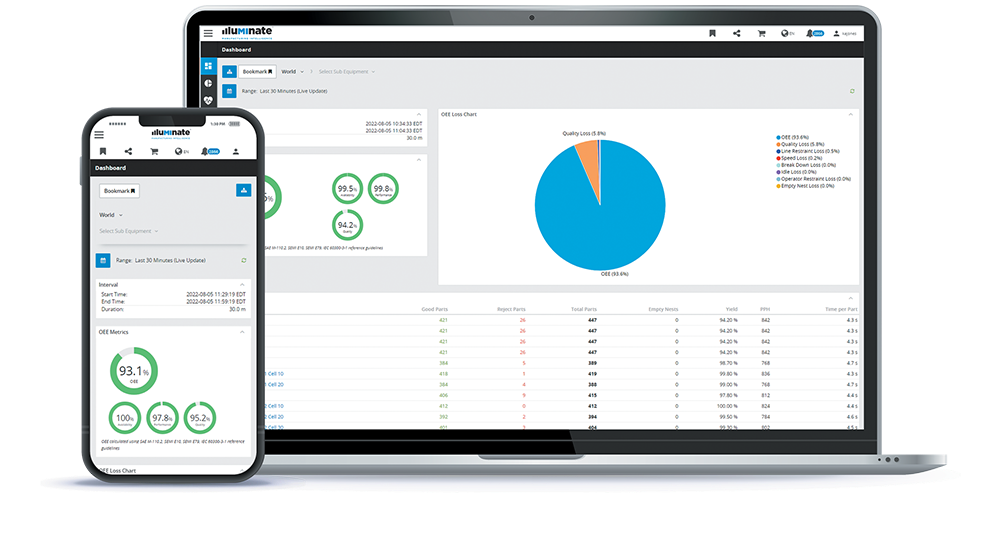

Illuminate™ Manufacturing Intelligence is an on-premise real-time production performance monitoring system that simplifies the collection and analysis of data from automated manufacturing systems. The flexible, scalable architecture of Illuminate software can be deployed on a single machine or extended across the entire plant floor for system-wide operational visibility and insight.

Visibility into your equipment’s performance

Diagnose and make OEE better

Anticipate component degradation to head off stoppages

Identify and prioritize potential issues sooner

Capture availability and minimize unplanned downtime

Eliminate rejects causing most scrap & energy waste

Determine why and where to more effectively increase throughput